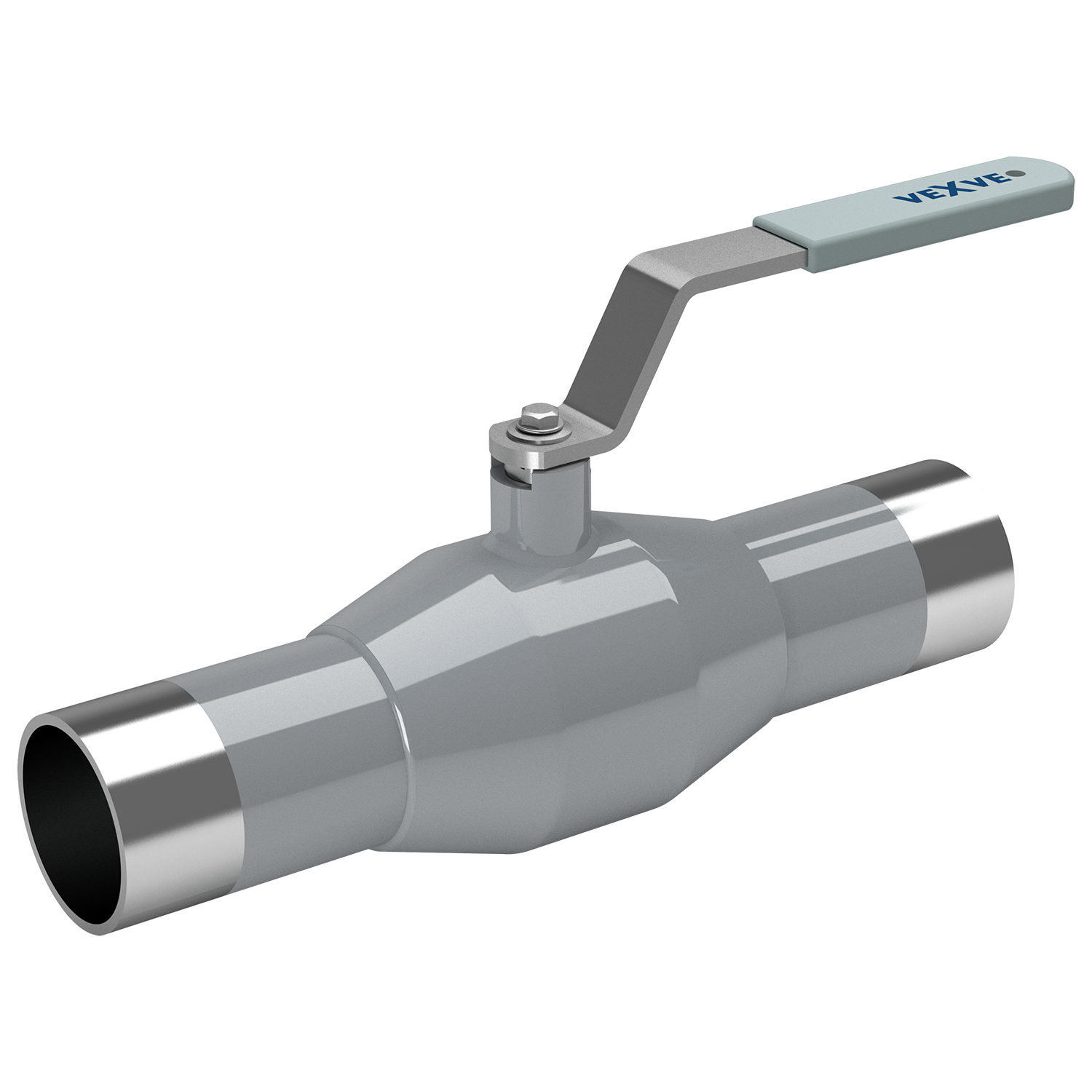

NAVAL Stainless Steel Ball Valves

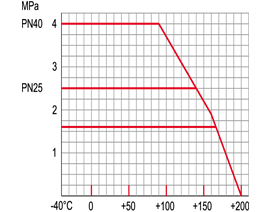

The stainless steel Navalball is a one-piece, all-welded, soft-seated on/off valve designed for a wide range of services in the chemical and process industries. It is used for oil, air and other liquids and gases which do not attack the valve at the temperatures and pressures specified in the diagram below.

Construction

The valve body, end pieces and valve neck are welded together to from a single unit and the blow-out proof stem is sealed by means of two FPM (Viton) O-rings, the upper one of which is replaceable. A PTFE thrust washer between the stem shoulder and valve neck prevents jamming and protects the stem seals from the media. Pre-loaded bevel washers hold the metal-encapsulated carbon-reinforced PTFE seat rings in contact with the ball.

Characteristics

One-piece welded design with no body joints to leak. Double stem seals to avoid stem leakage. Low lifetime cost due to long life, high leak-tight integrity and low initial cost. Stainless steel ball and stem. Carbon-reinforced PTFE seat rings. Stainless steel bevel spring washers. Easy operation due to low friction components. 100% factory body and seat tests. Easy to actuate. No modification or welding required. .

Stainless Steel Ball Valves versions

- Welding end/ Welding end

- Inner thread / Inner thread

- Flange/ Flange

- Welding end / Inner thread

- Welding end / Flange

- Inner thread / extended welding end made of steel